Servicing Your Centrifuge

Just like any other complex equipment, your centrifuge needs regular tune-ups. Get a trained technician to check your unit regularly. Some signs of damage are only visible to professionals. A trained eye can discern and repair any minor issues before they become large and expensive, ensuring your unit is safe to operate.

Depending on the frequency of use, you should aim to have your unit checked and calibrated every six to 12 months.

Understanding Centrifuges

As the name suggests, a centrifuge uses high speeds and centripetal force to separate liquids, spinning them at high revolutions per minute. The resulting gravitational pull causes the substances inside to move outward and split, from the densest at the bottom to the least dense at the top.

As centrifuges are important for diagnostic and research applications, even the slightest miscalibration can affect the results. Sourcing quality equipment from the outset is vital for the best results, and proper cleaning, care and maintenance of the equipment increases its accuracy and longevity.

Common Issues from Lack of Centrifuge Maintenance

Knowing how to maintain a centrifuge correctly is essential to increase durability and functionality. Modern centrifuges have relatively low maintenance requirements, but meeting these requirements is critical for safety and achieving the best possible results. Neglecting centrifuge maintenance can result in the following:

Impacting the performance and life span: Small miscalibrations or lack of maintenance can cause substantial and expensive damage to a centrifuge, which leads to wear and tear over time.

Risking injury: The centrifugal field, which accelerates the separation process, exerts a significant force on the rotor of your centrifuge. If any part of the mechanism fails, materials spinning at high speeds can damage the equipment and pose a risk to anyone in the area.

Centrifuge Cleaning and Maintenance

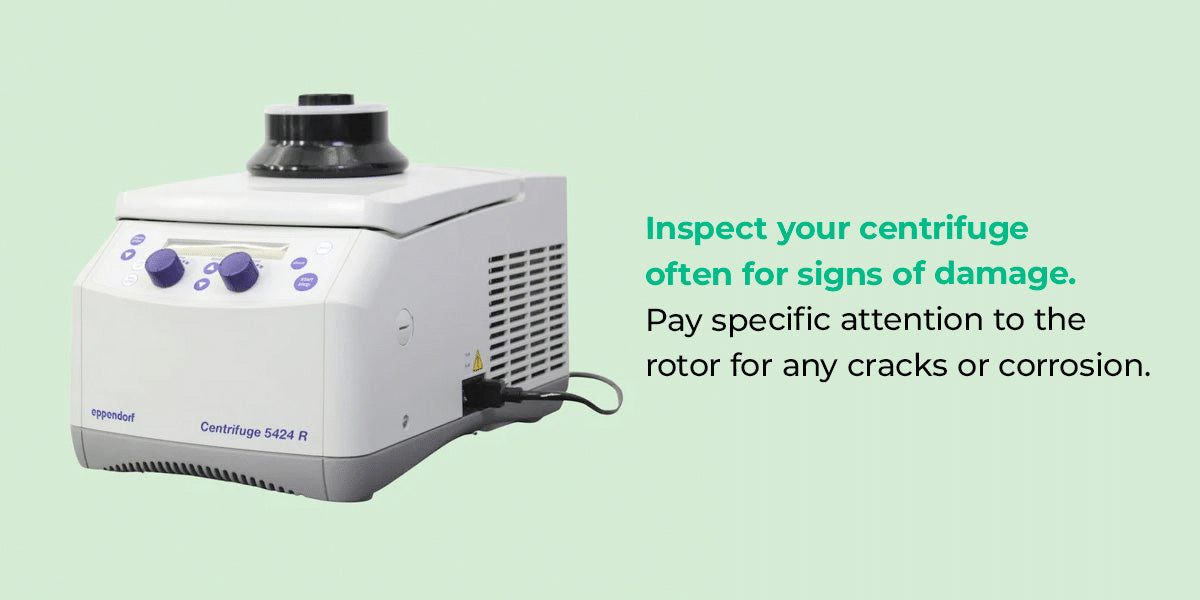

Knowing how to clean your centrifuge is one of the most essential aspects of centrifuge care. Keep the following tips in mind for correct maintenance and cleaning practices.

1. Cleaning Your Centrifuge

Neglecting to clean your centrifuge could result in corrosion and imbalances, leading to more dangerous equipment failures. Clean your centrifuge daily, or at least once a week, for the best results. Follow these simple steps to clean your centrifuge correctly:

- Wipe it down after every use, especially around the test tube area.

- Remove the rotor and any container holders while cleaning.

- Clean it thoroughly, including the interior mechanisms.

- Use a mild detergent and warm water to clean and dry it thoroughly.

- Wipe any spills immediately.

- Avoid caustic detergents, and don’t pour water into the bucket.

- Use a centrifuge lubricant for the bucket grooves and seals after cleaning.

- Disinfect the equipment regularly with an approved disinfectant.

The Role of Professional Services for Centrifuge Preventive Maintenance

While taking the proper steps to care for and maintain your centrifuge yourself is a key element of its longevity, professional maintenance is just as necessary. Regular servicing by professionals gives your equipment the best chance to last the entire length of its useful life, as they’re trained to see minor discrepancies and correct them in their infancy.

If you see something concerning during your routine maintenance, it’s best to consult a professional to ensure your centrifuge is still safe to use. In addition, scheduled maintenance every six to 12 months is vital, especially if you use your centrifuge regularly.

Correct Maintenance and Care of PCR

Regular maintenance is essential

Regular attention and care of these devices is vital mainly because any failure can lead to inaccurate results that can affect the veracity of scientific research. In the laboratory, where accuracy is paramount, the regularity and consistency of maintenance of this equipment can be the difference between a successful experiment and a costly failure.

In addition to the accuracy factor, regular maintenance prevents the occurrence of more serious problems that could lead to the need to purchase new equipment. This also saves costs in the long run, since this prevention prolongs the lifetime of the thermal cycler.

General steps for proper maintenance and care

The maintenance and care of PCR thermal cyclers mainly involves three steps: cleaning, calibration and periodic software checks.

Cleaning: Cleaning should be performed regularly to avoid accumulation of dust and other contaminants that may affect the efficiency of the equipment. Cleaning should be performed using mild, non-corrosive cleaning products to prevent any damage. Air ducts should also be cleaned to prevent overheating.

**Calibration: This step is vital to ensure the accuracy of the results produced by the thermal cyclers. Calibration should be carried out by trained professionals and temperature uniformity in all wells should be verified.

Software revisions: Keeping thermal cycler software up to date is crucial. Software updates often include improvements around the efficiency and accuracy of the machine.

Seek professional help when necessary

In some cases, problems with this equipment may be beyond the capabilities of lab technicians. It is in these cases when the help of an expert in laboratory equipment maintenance and repair is crucial. This is where investing in a professional maintenance service can be an excellent way to maintain the accuracy of results.

In short, proper maintenance of these devices is essential to ensure accurate results. By carrying out regular cleaning, machine calibration and constant software updates, the efficiency of the equipment can be increased.